How fabric printing affects sustainability, manufacturing timeline, minimum quantity, and budget

- The Purnaa Team

- Jan 20, 2020

- 5 min read

Updated: Jan 21, 2020

While printing can add a beautiful element to your product, you might be surprised at the complexity that printed fabric can add to garment manufacturing. If you haven't worked with prints before, here is a quick primer to help you know your options and how they will impact your product's sustainability, manufacturing timeline, minimum quantity, and budget.

There are many kinds of printing techniques, but you can generally think of them in three big categories: screen printing, block-printing, and digital printing.

Screen Printing: Screen Printing is a technique where a mesh, or screen, is used to transfer ink onto a base material, except where blocked by an impermeable stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the material and be pulled out of the mesh apertures as the screen springs back after the blade has passed. One color is printed at a time, so separate screens must be used to produce a multicolored design.

Plastisol-based inks are most common for garment decoration because they provide good color coverage on top of dark backgrounds and clear graphic detail. Unfortunately, they can have a plasticky feel and often use harmful chemicals (PVCs and phthalates). However, new non-PVC plastisol prints are now available on the market and it is worth asking your printer to use these kinds of ink. Water-based inks use less harmful chemicals but are more energy and water-intensive. They have a smoother feel, but can be difficult to print on dark colored fabrics.

Because each color of a screen print in added separately, screen printing is generally charged per color, per piece when on a finished garment and per meter on fabric. There is also usually a screen setup charge. Sometimes light colors printed onto dark background require two layers of ink and may receive a double charge.

Screen printing can be a fast and inexpensive option to apply to finished garments or fabric before cutting and sewing. Low quantities are usually feasible but might be expensive due to setup charges or if choosing many-colored designs in separate locations (such as front and back). Thus it tends to be best for simple designs across at least a few dozen pieces or dozens of meters/yards of fabric.

Block Printing: Is a traditional type of printing dating to ancient times across Asia. Its use on fabrics is now mostly limited to small artisan settings, often in India, Bangladesh, and Pakistan. Block printing involves creating a wood block with a mirror-image, relief pattern of the image to be printed and then applying ink to the block which is then pressed onto the fabric, usually by hand. This is easiest with repetitive patterns composed of one or a small number of motifs that are small to medium in size (due to the difficulty of carving and handling larger blocks). For a multi-color pattern, each color element is carved as a separate block and individually inked and applied. Block printing on fabric is usually done before garment sewing.

On the sustainability front, block-printing, being a fully manual process has a small carbon footprint. To ensure sustainability, ask your printer if they are using low-impact, azo-free dyes for their ink and ask about how wastewater is treated and how the fabric is dyed before printing.

Due to the time-intensive process of making new blocks and hand-printing block printed fabrics tend to have a high minimum quantity order requirement (several hundred meters or more) and are very expensive or impractical to produce in small quantities. Aligning each stamp with the next across the fabric can be difficult, so small gaps or overlaps are to be expected on hand block printed fabrics and designs with space between stamps are sometimes easier to produce.

If you are ordering south-Asian block printed fabric, it can be a highly seasonal product as it is often dried in the sun and therefore not available in the rainy seasons.

Digital Printing: Digital printing is a method of printing by applying ink to white or very ligh-colored fabric with a computerized printer, similar to home ink-jet printer technology, but usually much bigger. Digital printing on polyester fabrics is often called sublimation because the ink is first printed on paper and then a heat press is used to transfer the ink to the fabric, which chemically bonds with the poly-fibers at the high temperature. Printing on natural fibers is often called DTG (direct to garment) and involves inks that adhere to the top layer of the material rather than bonding into the fiber-like sublimation.

Digital printing is one of the most sustainable ways to add color and decoration to the fabric. It uses far less water than dying and screen printing, and because there is no screen to wash off there is no wasted ink as with screen printing. It also uses less electrical power to operate average digital printing machines versus rotary screen printing machines. Dye-sublimated digital prints have no wastewater but must be printed on polyester-based fabric through a transfer paper, so if using dye-sublimation ask if you can use a recycled polyester fabric and if the printer can recycle the transfer paper.

Digital printing is extremely flexible and can involve photo-realistic colors and designs and can be used to print precisely to a pattern. It can be available at very low quantities and produced very quickly. But it is generally more costly than screen and block printing as it involves expensive ink to cover the whole fabric and create bright colors.

A common quality concern with digital prints on fabric is that designs have significant amounts of white space or solid colors that can have small dots where ink either dripped onto white space unintentionally or lint or dust prevented ink adhering to the fabric in colored space.

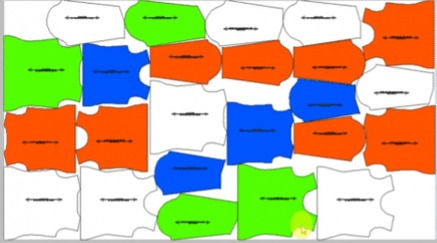

Material Consumption Considerations: Adding a print to your design can drastically change the efficiency of your material usage. Many prints have a directional orientation, meaning you can tell if it is upside-down or sideways. This might limit how your pattern pieces can be laid out for cutting. Consider the marker below. If there were a print on this fabric that had to be upright, the seemingly small limitations of not being able to flip the pieces over can greatly affect fabric consumption.

Additionally, sometimes you have a print with a specific element that needs to be placed on a certain pattern piece. Perhaps the main element of a print needs to be centered on a front shirt panel or a trim element needs to go along the hem of a skirt. These requirements not only increase material consumption but also labor costs, as the producers will have to carefully cut and sew around elements and may have more quality issues.

While designing a printed product, take some time to think through how the print design might be affecting your consumption.

Quality: Prints don't always come out perfectly. There are often misprinted sections with gaps, smudges, drips, misaligned elements and so forth. You'll have to decide with your manufacturer what level of misprint is acceptable or not, and depending on your tolerance level you might end up with sections of material that can't be used. Many printers will allow for a "spoilage rate" of a certain number of pieces or percent of fabric that can have issues. Make sure you are aware of this before confirming an order.

At Purnaa, we can help source the best print type for your needs. Submit a design idea to tell us about what kind of product you are interested in making and we will be happy to work with you to bring it to life.

Or learn more about material options in our recent Fabric blog series.